Projects

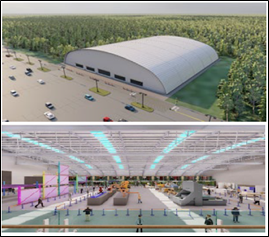

Smart Built Hub: Collaborative digital and physical platform

for offsite manufacturing network

Strongly supported by industry, the Smart Built Hub will be a unique facility, which will contribute to the advancement of digital construction technologies and provide a distinctive professionally oriented facility bringing together academia and industry as a collaborative network for off-site construction. With the contribution of 16 major industries – led by PT Blink Technology - and 9 universities, the project will result in Australia’s first industry-university collaborative facility for platform-based DfMA, and the only fully collaborative digital manufacturing software platform for off-site building construction. The facility will be formed of: (i) an actual lab, made of 1200sqm free-span high-ceiling shell structure with a control room connecting to the High-Performance-Computing (HPC) network and visualisation equipment; and (ii) a collaborative platform software as the operating and coordinating system for the facility.

Chief Investigator: Dr Pejman Sharafi, Prof. Bijan Samali, Prof. Srinath Perera, Prof. Vivian Tam, Prof. Mike Kagioglou

Digital Platforms for Net-Zero Construction Ecosystems

Through the establishment of the following 5 major crosscutting thematic research streams, the project aims to provide world-class strategic research and training infrastructure programs for transforming our built environment: (1) Decarbonisation: Process LCA, low waste processes, Optimisation, Sustainable procurement, Green tech integration, LEAN techniques, Adaptive systems, and Process energy simulation; (2) Industrialisation: Manufacturing, Automation, DfMA, Product standardisation Process standardisation, Physical prototyping, Digital fabrication, Digital prototyping, Productisation, and Mass customization; (3) Data Modelling: Big data, BIM, AI & AR, Data sharing, Cloud computing, Mobile interfaces, Generative design, DFD and ERD, and Process mapping; (4) Integration: IoT, Blockchain, Supply-Chain mapping, Digital quality management, Mission control, Collaborative design, and Smart contracts; (5) Implementation: LC Management, Software training, Workflow analysis, Business Process, Re-engineering, Maturity modelling, Business continuity management, and Legislation & Policies

Chief Investigator: Dr Pejman Sharafi, Prof. Vivian Tam, Prof. Bijan Samali, Prof. Srinath Perera,

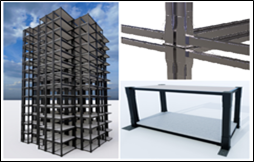

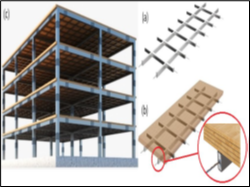

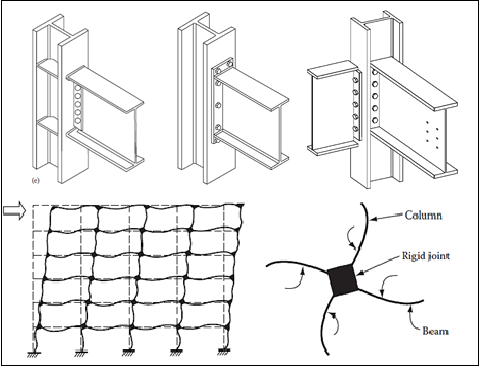

DfMA of an innovative flexible and adoptable

structural system for offsite construction of

multi-story buildings

This project is funded by Infratech Industries and is on the Design for

Manufacture and Assembly of a new flexible and adaptable steel

framed structural backbone for offsite manufacturing of buildings up to

20 stories. As a part of this project an innovative structural steel interconnection

is developed for moment resisting corner supported frames.

Chief Investigator: Pejman Sharafi, Dr Kamyar Kildashti

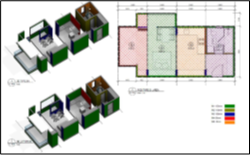

DfMA of prefabricated prefinished volumetric

units for offsite construction of modular buildings

This project is funded by Infratech Industries and is on the Design for

Manufacture and Assembly of a standardised prefabricated prefinished

pods for modular construction of multi-storey buildings. The Architectural,

Structural and MEP design, together with optimisation and standardisation

of components and sub-assemblies are a part of this project.

Chief Investigator: Dr Pejman Sharafi

Prefabricated energy efficient unitised façade systems for

multi-story modular buildings

This project is funded by Infratech Industries in which we develop some innovative

façade systems for prefabricated prefinished multi-storey modular construction of

buildings. The Use of both energy harvesting and energy efficient solutions together

with other constructional and structural challenges for DfMA of these systems

are considered in this project.

Chief Investigator: Dr Pejman Sharafi

Flexible low-carbon structural backbone for building offsite manufacturing

manufacturing

The project is funded by PT Blink Technology and is on the development of an innovative and eco-friendly hybrid structural backbone (using recyclable materials and reusable components) together with a cutting-edge digital platform for design for manufacturing and assembly. The outcome is a set of adaptable and standardised building components and subassemblies made of low-carbon hybrid/composite construction materials together with their manufacturing platform. The proposed system is expected to significantly facilitate flexibility in design, and adoptability to a wide range of applications in offsite construction, and contribute to the transformation of our building construction sector from a resource-intensive industry to an efficient, affordable, and sustainable ecosystem.

Energy Management and health monitoring system

for high-performance modular building systems

This project is funded by Infratech Industries and is on the development

of an automated energy management systems for unitised pods in

multi-storey modular buildings through the integration of energy harvesting

solutions and a network of embedded self-powered health monitoring system.

Chief Investigator: Dr Pejman Sharafi, Dr Maria Rashidi

Life cycle carbon emissions assessment of high-performance prefabricated prefinished modular buildings

prefabricated prefinished modular buildings

This project is funded by Infratech Industries and develops a comprehensive

program for assessing the green rating performance of the proposed

prefabricated prefinished modular building systems, leading to a smart

zero carbon building, while minimising construction waste. Through a life

cycle assessment, the program will adopt a cradle-to-grave approach for

the design and construction phase, operational and maintenance phase,

and finally, the disposal phase.

Chief Investigator: Dr Pejman Sharafi, Prof. Vivian Tam

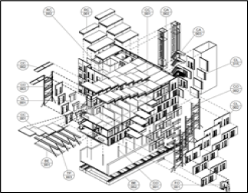

Innovative BIM-Oriented Platform for Design for Manufacturing

and Assembly (DfMA) of Prefabricated Residential Buildings

In this research project we develop a BIM-oriented platform with the capacity to be

used for a systematic DfMA that can be employed for a wide range of architectural

designs for low-rise residential buildings. This will be achieved by developing new

sets of generic standardised components and sub-assemblies in the form of BIM

libraries that can generate various designs while meeting the constructional, structural,

architectural, and urban planning constraints.

Chief Investigator: Dr Pejman Sharafi, Danesh Hedayati

Interactions between volumetric units in modular buildings

buildings

This project is funded by the Australian Research Council (ARC) as a Discovery Early Career Research Award (DECRA) and develops in-depth understanding of the interactions between volumetric units in modular buildings and specific criteria in relation to the considerations and expectations for the design of modular buildings’ interconnections and fasteners.

Chief Investigator: Dr Pejman Sharafi

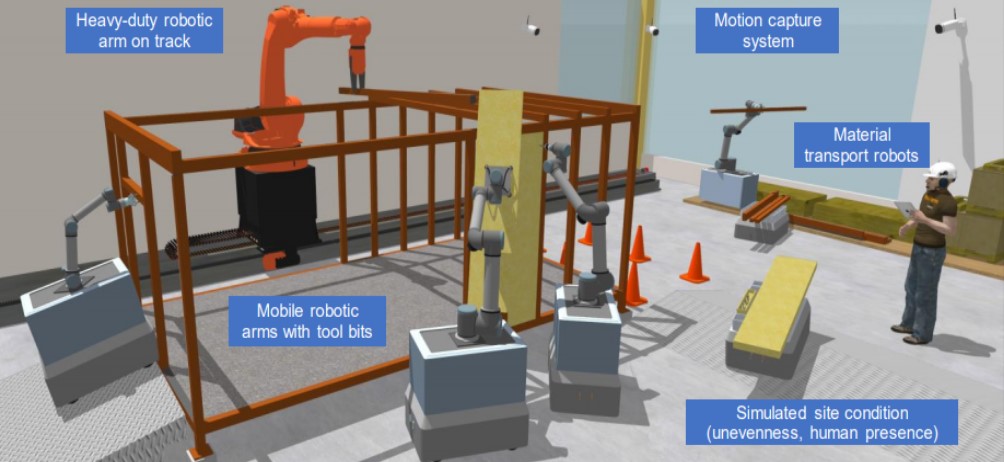

Collaborative robotics for structural assembly and construction automation

Collaborative robotics for structural assembly and construction automation

As a collaborative project between seven Australian universities, this ARC-LIEF funded project is the development of a cutting-edge facility to provide a unique platform on research and development for structural assembly and construction automation. It features by a flexible and adaptive design and instrumentation of structures and space for a team of collaborative robotics in an interactive environment to achieve automated prefabrication, assembly and building.

Investigators: Prof. Yu Bai (Monash); Dr Pejman Sharafi; et al.

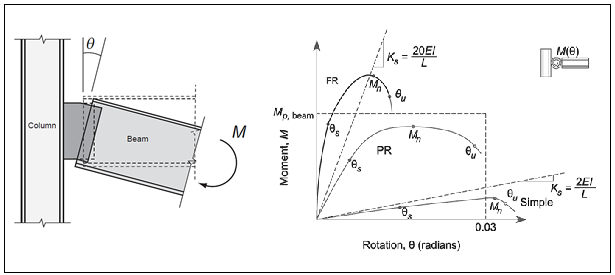

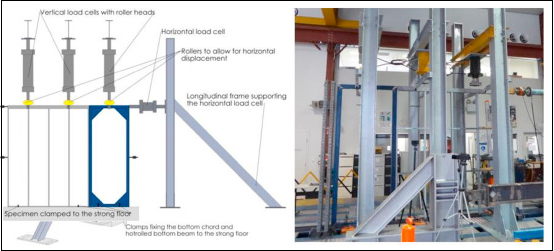

Classification and prequalification of modular steel connections

Classification and prequalification of modular steel connections

This project aims to determine specific criteria for the classification of connections for strength, stiffness and ductility and develop in-depth understanding of the factual considerations for the structural design of prefabricated modular steel buildings with regard to the requirements for stability.

Investigators: Mostafa Farajian; Dr Pejman Sharafi

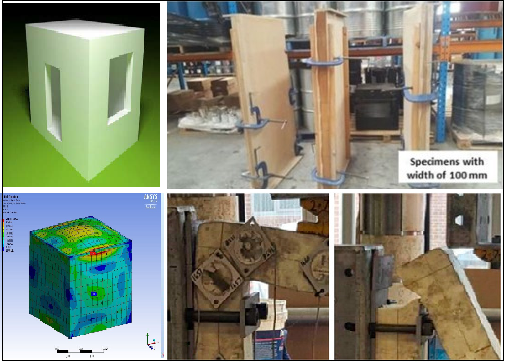

Improving Flexural Performance of Moment-Resisting Joints in Volumetric Modular Steel Buildings

Improving Flexural Performance of Moment-Resisting Joints in Volumetric Modular Steel Buildings

This project focuses on improving the structural performance of modular interconnections, while addressing the constructional and architectural constraints. It aims to develop innovative solutions to improve the structural performance of modular steel buildings.

Investigators: Parham Mohajerani; Dr Pejman Sharafi; Prof Bijan Samali

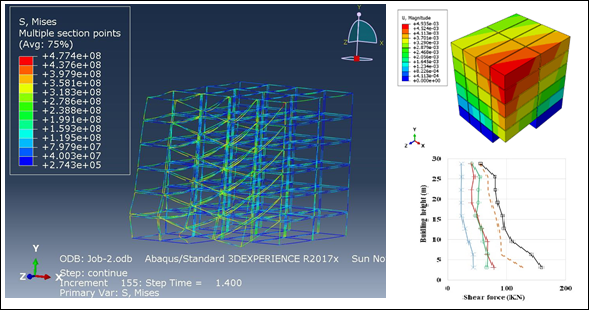

Robustness of corner-supported modular steel buildings

Robustness of corner-supported modular steel buildings

This project studies the minimum requirements for assessment and verification of stability and robustness of prefabricated modular steel buildings through investigation of the collapse capacity and failure mechanisms in a variety of notional removal of elements.

Investigators: Mohammad Alembagheri; Dr Pejman Sharafi; Prof Zhong Tao

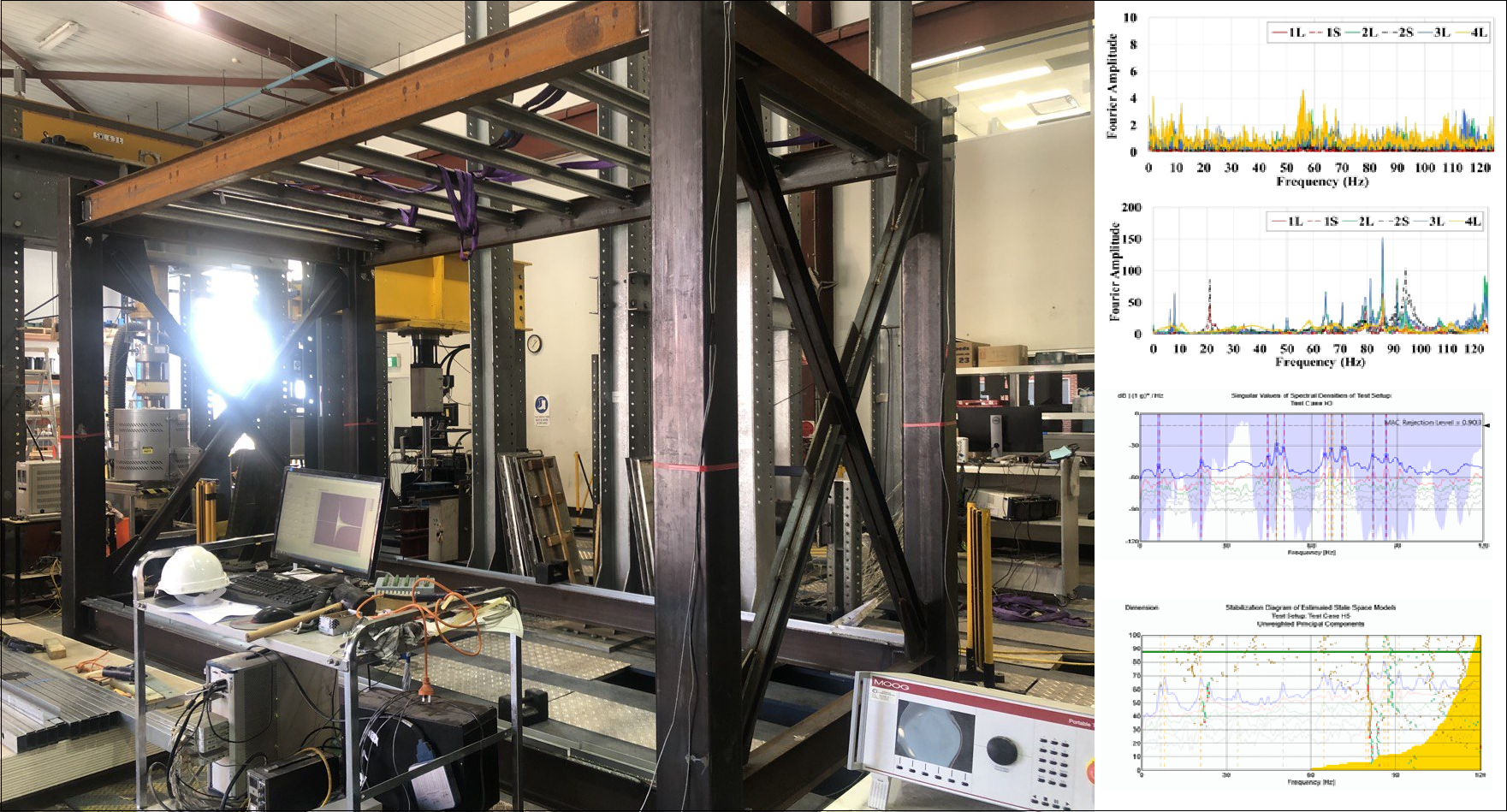

System identification of steel modular buildings

System identification of steel modular buildings

In this project identifies the steel modular buildings characteristics through investigating the natural and dynamic properties of their structures. The investigations involve full scaled experimental and numerical models using system identification techniques under the context of operational modal analysis (OMA).

Investigators: Mohammad Alembagheri; Dr Pejman Sharafi; Dr Maria Rashidi

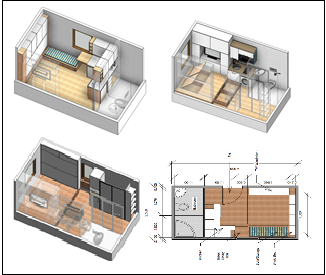

Modular sustainable tiny houses

Modular sustainable tiny houses

This project is focused on the design of innovative modular sustainable houses, which are adaptable to variety of applications (homelessness, tourism, emergency shelter, etc.) and environments

Investigators: Fariborz Moshfeghinezhad; Dr Pejman Sharafi; Dr Nariman Saeed; Dr Hadi Hoseiniamoli; Dr Ehsan Sorooshnia; Faezeh Shateri

Modular foam-filled panelised systems for rapidly

assembled post-disaster housing

An innovative deployable modular system for rapid-assembly building

construction is developed in this project, which can be quickly-assembled

as post-disaster housing or semi-permanent shelters.

Investigators: Dr Saeed Nemati; Dr Pejman Sharafi; Prof Bijan Samali

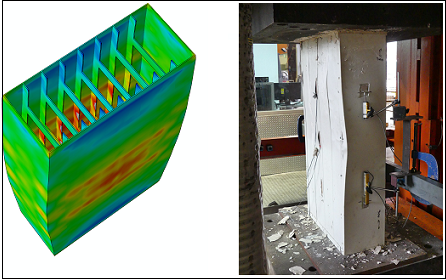

Prefabricated hybrid steel wall panels for mid-rise construction

Prefabricated hybrid steel wall panels for mid-rise construction

This project investigates an innovative lightweight hybrid steel wall panel system (HWPS) made of a hot-rolled steel panel and a cold-formed steel panel developed in this project; and its applications as a lateral load resisting system for midrise construction in earthquake prone regions are investigated.

Investigators: Dr Mina Mortazavi; Nima Usefi; Prof Hamid Ronagh; Dr Pejman Sharafi; Prof Bijan Samali

Protective composite wall panels

This research-consulting project is conducted in collaboration with the university of Wollongong, FlexiRoc Australia, and Stone Security, and focuses on the design of protective wall panels for protection against blast, ballistic, forced entry, impact, weapon effects, fire and seismic loads and can be used to mitigate risk against accidents, natural disasters and direct attacks.

Investigators: Prof Hamid Ronagh; Dr Pejman Sharafi; Prof Alex Remmenikov (UoW), Gary Bullock; Khaled El-Domiaty

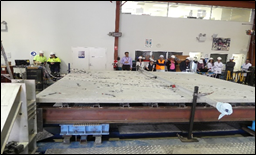

Lightweight composite floor diaphragms

Lightweight composite floor diaphragms

In this research project a new lightweight composite floor is developed for application in LSF construction and mid-rise construction. The performance, with regard to vibration, diaphragm action and the effects on load distribution is investigated through experimental tests and numerical modelling.

Investigators: Soheila Peyrovi, Prof Hamid Ronagh; Dr Pejman Sharafi; Prof Bijan Samali

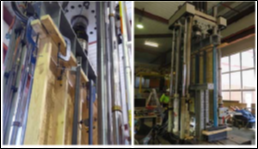

Timber frame reinforcement solutions for mid-rise modular construction

Timber frame reinforcement solutions for mid-rise modular construction

Solutions for the enhancement of the compression perpendicular to grain and the effectiveness of some different reinforcement techniques for improving the bearing strength of these members are investigated in this project through extensive experimental tests and numerical modelling. The aim is to enhance the timber frame performance for applications in mid-rise modular construction.

Investigators: Farnaz Alinoori; Dr Fred Moshiri; Dr Pejman Sharafi; Prof Bijan Samali

Structural performance of permanent modular formwork systems

Structural performance of permanent modular formwork systems

This research-consulting project is conducted under the ARC Industrial Transformation Research Hub for Nanoscience-based Construction Material Manufacturing (the Nanocomm Hub) for CRS-AFS systems and evaluates and improves the structural performance of permanent formwork systems, Logicwall and Rediwall, through advanced numerical simulations and experimental tests.

Investigators: Dr Kamyar Kildashti; Prof Bijan Samali

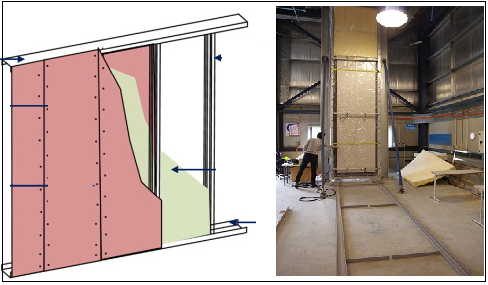

Prefabricated composite LSF wall panels

Prefabricated composite LSF wall panels

In collaboration with Kenauf Australia, this research-consulting project is designed to first develop an advanced vacuum testing facility for experiments on panelised wall and floor systems, and then extensive experimental program on the design of composite LSF walls sheated with gypsum boards for various boundary conditions are performed.

Investigators: Prof Hamid Ronagh; Dr Pejman Sharafi; Dr Nariman Saeed

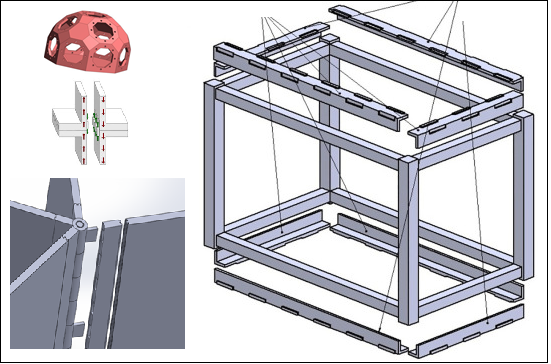

Innovative joints for modular construction

Innovative joints for modular construction

This project seeks development of innovative connections to facilitate the assembly and disassembly of components such as walls, floors, and volumetric units in modular construction. Conceptual and detailed designs, numerical simulation and experimental verifications of a number of modular connections are being carried out in this project to address the existing shortcomings in the area.

Investigators: Dr Pejman Sharafi; Dr Mina Mortazavi; Dr Saeed Nemati; Reza Bani Ardalan; Fariborz Moshfeghinezhad