Environmental Chamber and Composite Laboratory

The Environmental Chamber and Composite Laboratory at Centre for Infrastructure Engineering is designed for manufacturing composite materials and evaluating durability of different materials in harsh environments. Composite manufacturing methods including laying-up of prepreg materials, vacuum bagging, wet lay-up and resin infusion. The lab has been established this year, the scope and capabilities include:

Thermal press is use for processing for processing thermoplastics materials which require a high temperature and high pressure. The press has a 400 x 400 x 200 mm working volume reaching temperature up to 300 °C and pressure up to 25 metric tons. The thermal press has an integrated water-cooling system, which allows fast cooling rates. The PID temperature controller system allows both the heating and cooling rates to be controlled during processing.

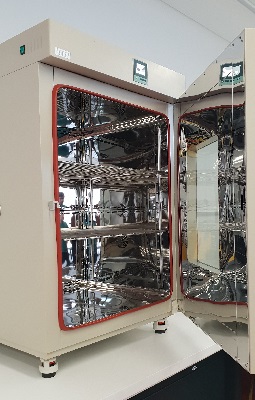

The lab includes a large oven with the internal dimensions of 700 x 640 x 900 mm for processing composite materials, such as curing of thermoset resins and high temperature resin infusion. The oven can reach a maximum temperature of 300 °C.

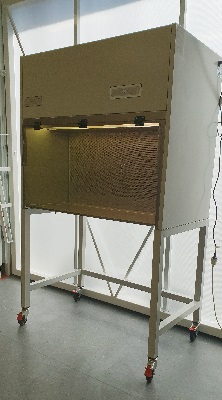

Large fume cupboard is used for the process which requires high ventilation to be undertaken. These typically consist of mixing resin component, or the use of solvents for cleaning tools.

ENVIRONMENTAL CHAMBER

Internal Dimensions 1000 x 1000x 1000mm

Temperature: -20°C R150 °C

Humidity: 30%∼98%R.H

UV (340nm)

Water Spray Time: 0∼9999min,

Programable

Salt Spray Chamber

Internal Dimensions 1000 x 1000 x 1000mm

Programmable spraying

Please direct any composite research enquiries to: